| Materials: | Carbon steel, Stainless steel |

| Size: | Customized as per detailed sizes or drawings |

| MOQ: | 1,000pcs above, depends on products or dimensions |

| Sample lead time: | 3-7 working days mostly |

| Massive lead time: | 10-15 working days mostly |

| Trade terms: | EXW/FOB/CIF/CNF/FCA/DAP/DDP/DDU |

| Package: | PE bags + brown carton + pallets or customized as demands |

Three-hole nuts, also known as three-ear nuts, are a special fastener with three deep holes and three surface protrusions, which makes it convenient to use to lock bolts. This design not only enhances its fixing strength, but also makes it popular in occasions where frequent disassembly and assembly are required.

Material and manufacturing process

Three-hole nuts are usually made of high-strength metal materials to ensure that they can withstand large tightening forces and repeated use requirements. During the manufacturing process, cold heading forming process is usually used to ensure the quality and durability of the nuts.

Application fields and advantages

Three-hole nuts are widely used in many fields, including mechanical equipment, metal structures, wood connections, etc. Especially in occasions where frequent disassembly and assembly are required, its convenience makes three-hole nuts popular. In addition, three-hole nuts can also be used to fix composite panels of refrigerated trucks, such as discs with a diameter of 27mm and internal thread diameter of 8mm.

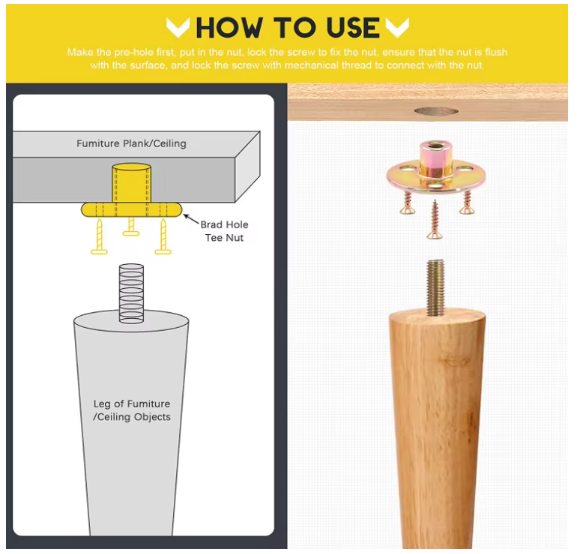

Installation method and usage scenarios

The installation of three-hole nuts is relatively simple. Just put it on the bolt or screw and rotate it with a wrench or spanner to complete the installation. Due to its strong fixing force, reusability and easy installation, three-hole nuts are widely used in mechanical equipment such as aviation, ships, and automobiles.